|

|

Recuperative Gas Burner System

• Increased efficiency and fuel economy

• Under cold start conditions, unit can fire at up to 50% extra to maximum hot

air rating for rapidheat-up

• Wide stability limits and excess air and gas capability

• Easy installation

• Rugged construction

• Up to 30:1 turndown

• Excess air/gas ratio options

OPERATION

The Nu-way Multiplex recuperative burner system offers the option of a self-recuperative burner or a separate recuperator and burner.Therecuperative system is designed to extract waste heat from the flue products of medium to high temperature industrial processes and to pre-heat the cold combustion air, returning heat to the process and so considerably reducing the fuel usage. The system is designed for the modernisation of existing furnaces or for use in new, energy-efficient furnace designs. Applications include forge furnaces, reheating furnaces, intermittent kilns, soaking pits, heat treatment furnaces, crucible furnaces and indirect heating processes. Self Recuperative Burner

• Eliminates insulated duct work

• Heat exchange takes place at the burner, not remotely, less heat loss Separate Recuperator

• Can retain existing air flow patterns in furnace

• Can use more than one burner per recuperator

• Can be used with specialised oil and gas burners.

|

Multiplex 20 kW-12 MW MP Series

Gas, Oil and Dual Fuel Burner

• Exceptional flame stability

• Wide turndown (up to 30:1)

• Low air and gas pressure requirements

• Inner assembly easily removed

• Combustion tunnel options, heat resistant metal, refractory, silicon carbide

• Low, medium and high velocity options

• Excess air/gas ratio options.

The MULTIPLEX burner has been designed to achieve a high degree of stability over a wide turndown range from relatively low service inlet

pressures. The complete operating range of the standard burners at required pressure is given in the information included in this data sheet. Gas and air flows may be controlled by a gas proportionator and air butterfly valves, or for maximum turndown, controlled by a mechanical or electronic ratio control system. For high excess air operation the air valve would normally be left fully open and controlled by the gas valve only, thus providing a relatively constant volume of combustion products in the furnace throughout the operating range.

BASIC BURNER

The basic burner is supplied without a combustion tunnel. It is suitable for mounting directly to the wall of the application, the combustion tunnel

being formed by a suitable hole in the furnace wall.

FUEL

Burners can be supplied for all commercial gases, (light) oil, or dual fuel.

COMBUSTION TUNNELS

Multiplex burners are available with a number of combustion tunnel materials and the following is intended only for general guidance. All sizes, in all materials, can be supplied with extended projection.

METAL COMBUSTION TUNNELS

For low temperature applications up to 450°C, standard stainless steel material can be used for the combustion tunnel. For high temperature applications up to 900°C, a high quality heat resistant stainless steel is available.

|

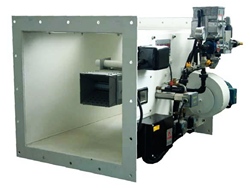

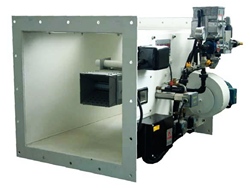

Multiplex 20 kW-4.4 MW FMP Series

Packaged Industrial Process Gas Burner

• Fully automatic packaged assemblies

• On/off, high/low or modulating control

• Up to 20:1 turndown

• Fan scroll up (standard) or down. Valve train right or left (other arrangements to special order)

• Can be wired to terminal box for use with separate controls

• Combustion tunnel options, heat resistant metal, refractory, silicon carbide

• Excess air/gas ratio options

• Low and medium velocity options

• Continuous running fan to prevent over-heating when burner not in operation (optional)

OPERATION

The FMP range of packaged burner units is based on the proven range of MULTIPLEX industrial burners. The burners are of rugged construction and are suitable for a wide range of industrial process applications including ovens, incinerators, furnaces, etc.

The FMP burners use the Multiplex gas nozzle together with an integral fan and packaged valve train. This data sheet refers to the range of eight packaged burner sizes from FMP5 to FMP150, giving a nominal output from 20 kW to 4.4 MW.

FUEL

Burners can de supplied for all commercial gases, and in addition can be produced for use with other gases such as mines gas, bio gas and producer gas.

CONSTRUCTION

FMP burners can utilise either medium or low velocity combustion tunnels. The MP burner with a separate fan should be used for high velocity applications. METAL COMBUSTION TUNNELS For low temperature applications up to 450°C, standard stainless steel material can be used for the combustion

tunnel. For high temperature applications up to 900°C, a high quality heat resistant stainless steel is available.SILICON CARBIDE TUNNELS

For high temperature applications up to 1300°C, ceramic fibre-lined furnaces and kilns, silicon carbide combustion tunnels are available. Medium velocity only up to FMP15 only. High and low velocity options not available.

|

Multiplex 20 kW- 4.4 MW

MPHA Series

Hot Air Gas Burner

• Preheated air up to 700°C

• Exceptional flame stability

• Wide turndown up to 30:1

• On ratio, excess air or excess gas operation

• Low air and gas pressures

• Inner assembly easily removed

• Range of eight burner sizes giving maximum nominal outputs of 60 kW to 4.4 MW

OPERATION

The MULTIPLEX hot air burner has been designed to achieve a high degree of stability over a wide turndown range from relatively low service inlet

pressures. The complete operating range of the standard burners at required pressure is given in the information included in this data sheet. Gas and air flows are normally controlled by double diaphragm proportionators measuring mass flow of air and gas to compensate for air temperature variations.

FUEL

Burners can be supplied for all commercial gases, (light) oil, or dual fuel.

REFRACTORY COMBUSTION TUNNEL

These burners are usually supplied with high temperature refractory quarls suitable for temperatures up to 1700°C.

|

Energystream 100 kW-20 MW

ES/ESX

Nozzle-Mix Gas Burner

• High output capacity up to 600 kW per 300mm

• Wide turndown range

• Versions available for fixed air/gas ratios (including stoichiometric) and gas only control

• Modular construction based on nominal 152mm and 305mm increments with tee and cross elements

• Minimum service maintenance

• Available in package forms with or without combustion air fan

• Side or rear air inlet for combustion air fan versions to suit customers’ application

The Nu-way ENERGYSTREAM burners represent a new concept in direct fired air heating. They are nozzle mixing line type modules, available in straight or cross pattern that can be built into an infinite variety of patterns to suit duct dimensions and application constraints. The basic ES burner head comprises burner section, integral pilot assembly, spark ignition and either flame probe or UV flame monitoring. The ES burner package may also include a combustion air fan and gas control train, and can be mounted onto a sideplate for ease of installation in ducts.

Modulating or high/low control options are available for gas and air control, or gas only control. Combustion air for the burner would normally be

provided by a blower mounted either directly to the burner head or at a position adjacent to the duct. Stainless steel casings and nozzles are additional options to allow operation at higher temperatures.

|