TITAN AS PACKAGE STEAM BOILER

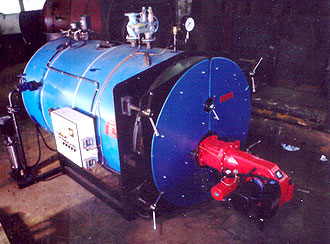

For processes that require up to 10tons/hr of steam, the Titan AS represents our most popular model because of to its versatility, robust construction and efficient operation.

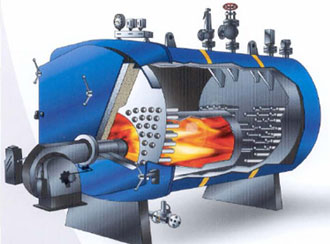

Adopting the Reverse-Flame principle, the Titan AS allows hot flue gases to make 2 passes within its pressurised combustion chamber and a third and final pass through its fire-tubes on its exit, thus maximising the time and absorption of heat within the boiler.

KEY FEATURES

* Designed and manufactured to the latest international standards (BS2790)

* Operating pressures of either 150psig or 250psig

* Full wetback design thus minimising radiation heat loss and refractory maintenance

* Spiral agitators in fire-tubes to enhance heat transfer

* Large furnace volume assures high combustion efficiency and for a wide variety of fuels to be burnt efficiently

* Compact in construction yet designed for easy access, important for internal inspection, cleaning and maintenance

* Full automated operation provided for control for burner system, steam pressure and for failsafe operation

* Food processing

* Textiles

* Hotels

* Edible oil refineries

* Biodiesel processing

* Packaging

* Hospitals

* Pharmaceuticals

| Models | Steam Capacity | |

| lb/hr (F&A 212ºF) |

Kg/hr (F&A 100ºC) |

|

| AS125 AS200 AS350 AS500 AS650 AS800 AS1000 AS1200 AS1400 AS1600 AS2000 AS2400 |

1250 2000 3500 5000 6500 8000 10000 12000 14000 16000 20000 24000 |

567 907 1588 2268 2948 3629 4536 5443 6350 7258 9072 10886 |